Mechanical Testing Lab

| Head | Leading Research Scientist – Ivan Sergeichev |

| Team |

|

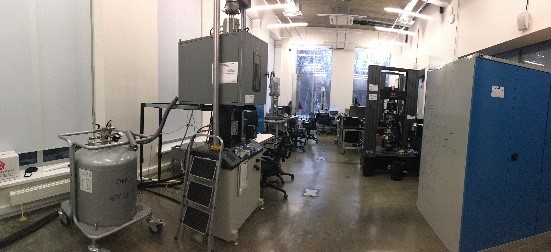

Description Common view of Mech. Test. Lab. Common view of Mech. Test. Lab. |

Mission: Support all scientific, R&D, educational activities in Skoltech in field of mechanical testing. Certification of new materials. Support of development and verification of constitutive material models and failure criteria. Development of test method relative to new materials.

Objectives

Ongoing research activities

|

| Educational activities | List courses that are based on or use the laboratory facilities with a brief description of each and links to full information: |

| Available experimental and computational capabilities and equipment | Testing machines: |

|

SHIMADZU USF2000 – a fatigue machine with an ultrasonic actuator for testing of metals. Applies 1010 cycles in several days. |

|

INSTRON 8801 – a servohydraulic machine for static and dynamic tests. Equipped with a temperature chamber capable of maintaining temperatures from -100 to +350 °C. Loads up to 100 kN. |

|

CEAST 9340, CEAST 9310 – drop towers. Designed to produce damage with energy from 0.15 to 405 J. Can perform standard Charpy and Izod tests. |

|

INSTRON 5969 INSTRON 5985 – servomechanical testing machines for static tests of any material in compression, bending and tension. Loads up to 50 kN and 250 kN correspondingly. |

|

DEBEN MICROTEST – a miniature horizontal-oriented testing machine for testing of single fibers or thin films while watching the tested object in an optical or scanning electron microscope. |

|

INSTRON E3000 – a testing machine for static and dynamic tests. Loads up to 3 kN. |

|

Digital image correlation system – a complex consisting of two cameras, an analog-digital converter and a computer with pre-installed software on a mobile platform. Connects to any testing machine. Capable of reconstructing a 3D picture of strains on a stressed sample that has a special painting on it. |

| National Instruments PXIe system for strain gauge measuremets. | |

Collaborators in industry and academia |

Collaboration with industries and academia that are potential users of new material and technologies are being vigorously pursued. Several modes of interaction are envisioned between the MTL and industry partners, including adjunct professorial appointments, research exchange programs, the establishment of an industrial advisory board, workshops to review research results, and summer job placements for graduate and undergraduate students. |

| Other | Positions: Links to the office. |