Thermal Spray Lab

Welcome to Laboratory of Thermal Spray Coatings at Skoltech’ Center for Design, Manufacturing, and Materials.

|

|

| Core Research Team | Dr. Dmitry V. Dzhurinskiy, Assistant Professor Petr Shornikov, Senior Engineer Stanislav Dautov, PhD, Research Engineer |

| Laboratory Description | The Thermal Spraying Team is engaged in R&D activities focusing on advanced thermal spraying processes development, parameters optimization and industrial applications. Our team is carrying out fundamental and applied research in order to understand specific features of coating structure formation, properties evaluation, and performance relations based on engineering methodologies. The laboratory is equipped with one-of-kind thermal spraying processes along with diagnostic accessories to monitor technology’ process parameters. This enables to utilize scientific competencies, process simulation and laboratory practices to deliver with innovation capacity toward leverage manufacturing industry and production needs. |

| Educational Activities | Course Title: Thermal Spray Coatings

Course Description: This practically-oriented course is intended to familiarize graduate students with an understanding of thermal spray processing science and front-line research topics, with attention to latest development and innovations in the field. The second purpose of this interdisciplinary course is to give the students technological/engineering perspectives of thermal spray applications and practice. Learning objectives: Develop knowledge and specific hands-on skills in thermal spray processing of materials; Perform spraying of single- and multi-phase compositions, ceramics, metal-matrix, and functionally gradient materials; Carry out physical properties evaluations of sprayed deposits; Build finite element model of spraying nozzles and perform computational fluid dynamic (CFD) analysis to find optimal process parameters; Use and practice modern principles of advanced manufacturing technologies by performing computer-aided manufacturing (CAM) tasks. |

| Current Research Interests | 1. Developing practice-oriented numerical models and process digital replicas (Digital Twins) for thermal spraying processes.

2. Parameters optimization for aqueous suspensions and solution precursors spraying to produce multi-phase layered- and columnar- like structures. 3. Design of powder feedstock materials and functional coatings development intended for industrial applications and requiring resistance to wear, heat, and corrosion. |

| Laboratory Capabilities | The laboratory possesses a spraying booth equipped with an industrial ABB and FANUC 6-axis robots and most standard thermal spray application systems such: • Atmospheric plasma spray (APS); • Wire-arc spray; • Flame spray; • Cold gas dynamic spray (CGDS).

In 2021 a high velocity oxy-fuel spray (HVOF hydrogen fuel) system will be launched, which allows deposition of extremely high density and low oxide content coatings. Along with the technological equipment, the laboratory has an extensive range of process diagnostic and coating characterization equipment. |

| Join a Team | We are currently looking for enthusiastic students (at both MSc and PhD levels) and postdoctoral fellows to join a research group at the laboratory of thermal spray coatings. Please contact Dr. Dmitry Dzhurinskiy at *protected email* |

Process Simulation

Thermal spray technology implies different scales of physical phenomena which occur simultaneously during coating deposition process. Hence, the particular process cannot be analyzed by deployment of a single numerical model. Despite of that the entire spraying process must be divided into sub- processes, which should be modeled using different approaches.

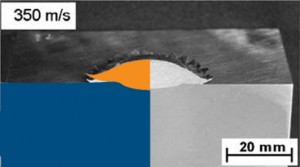

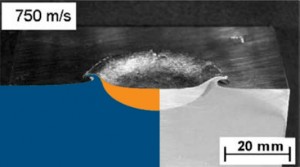

Below is some results from our previous work of developing a digital replica (Digital Twin) for Cold Gas Dynamic Spray process (CGDS). CGDS is a unique coating technology in which spray particles in a solid state are deposited on a substrate, via high velocity impact, at temperatures lower than the melting point of the powder materials and thereby prevent in-flight oxidation of feedstock materials.

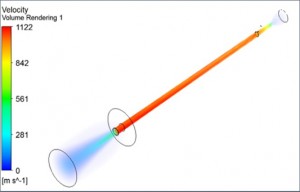

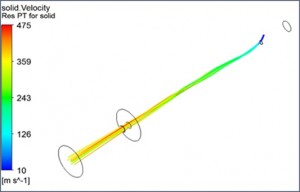

Here are results of computational fluid dynamic (CFD) analysis illustrated a velocity of carrier gas along with the velocity distribution of powder feedstock materials.

|

|

Results of numerical simulation for 2D axisymmetric model in comparison to experimental data (https://doi.org/10.1016/j.actamat.2005.10.005)

|

|

The research group is focus an attention on the processes analysis and strategies formulation for assurance optimized design and functional coating quality for various areas of industrial applications.