Enhanced Oil Recovery

Laboratory Setup for Investigation of Thermal Oil Recovery Processes

|

This complex of equipment let us to proceed with In Situ Combustion, High-Pressure Air Injection (HPAI), Steam-based processes for heavy-, medium- and light-oil reservoirs and Hybrid processes, corefloods for CO2, flue gas, hot water or hydrocarbon gas injection tests.

Features:

|

The PIK-OFP/EP analysis of filtration-volumetric and electrical core properties

Geomechanics

MTS 816 Rock Mechanics Triaxial Test System

|

Fully integrated high-force test systems optimized for carefully controlled characterization of brittle materials.The MTS Model 816 system is engineered for rock mechanics research testing that involves smaller samples. It can be configured for uniaxial, triaxial or direct shear testing, and its compact frame is easy to locate in the lab. Features:

|

Core Analysis

The PIK-SK plant for core samples saturation

The PIK-PP Automated Porosimeter and Permeameter

Capillary pressure refrigerated centrifuge

Petrophysic and geochemistry lab

Geospec 2 NMR for core analysis

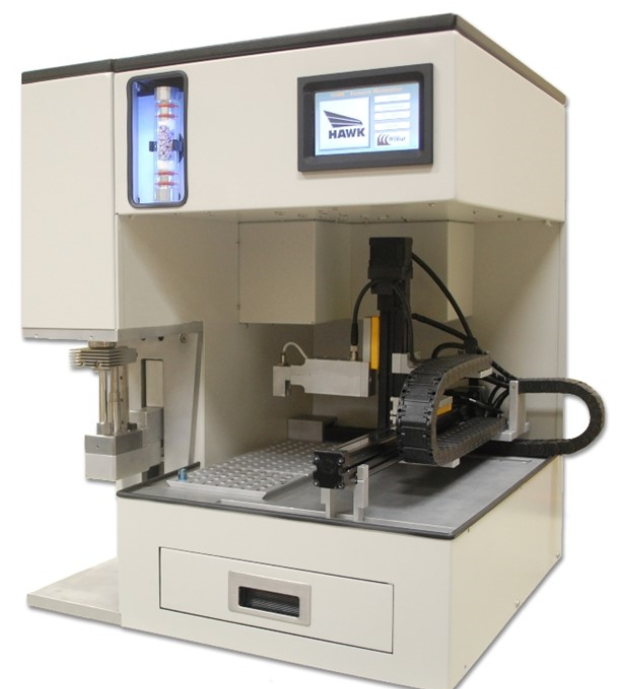

HAWK Resource Workstation

|

HAWK Resource Workstation provides accurate and rapid analysis on cuttings, core & outcrop samples. With portability to boot, HAWK can be used in the lab or on-site. The HAWK Instrument provide us with the basic data for formulation of geochemical logs that is needed to classify the type of reservoir rock that your drill bit encounters. Application of data from HAWK leads to the successful identification of producible Shale Oil Resource Systems.

Features:

|

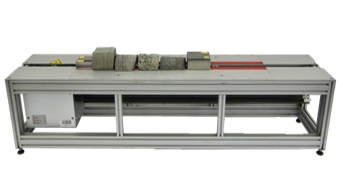

Optical scanner for thermal rock property study

|

The optical scanning instrument is designed to investigate thermal properties of solids, in particular – rock samples or drilling cores. The instrument provides continuous profiling of thermal properties – thermal conductivity (along and perpendicular to bedding), thermal diffusivity, volumetric heat capacity, inhomogeneity coefficient and thermal anisotropy coefficient – for solids on their cylindrical or flat surface. The uniqueness of the instrument is in the fact that this method of investigation is non-destructive and non-contact, no mechanical treatment of the sample is required during preparation of the sample, no mechanical effect (for example: axial compression) exists during the measurements, the absence of contact with the sample provides a precise level of the measurements. This piece of equipment was developed by professor Yuri Popov.

Features:

|

DTC-300 Thermal Conductivity meter

Quartz Dilatometer DKT-40

CT System v|tome|x L240

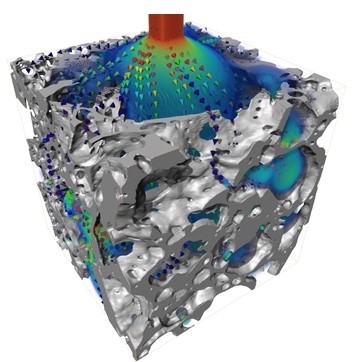

CT of porous sample with a resolution of 5 microns/ Fluid flow simulation option is added (Avizo XLab Hydro). Flow velocity vizualised in colores – from blue to red.

CT of porous sample with a resolution of 5 microns/ Fluid flow simulation option is added (Avizo XLab Hydro). Flow velocity vizualised in colores – from blue to red.